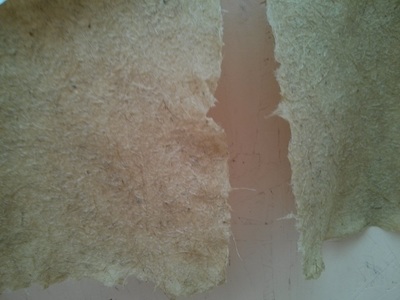

A few months back we were contacted by the Ned Jaquith Foundation about teaching a bamboo papermaking workshop for their annual campout and BBQ potluck fundraiser. Yesterday we had the pleasure of teaching the workshop and connecting with 6 wonderfully enthusiastic and engaged students. Doing offsite workshops like this is something we really enjoy, and want to do more of, as it gives us the opportunity to reach new audiences and spread the joy of papermaking. The workshop was 2.5 hours, so we knew we needed to bring pre-prepared pulp to work with during the class. About a month ago we visited the beautiful Bamboo Garden in North Plains, OR to get a feel for what our set up process would be for the class. We also scored some bamboo canes and leaves (fresh green and dried brown) from their compost pile that we brought back to our studio for processing. We ended up using a little over 1 pound of dry canes to process into pulp. We also prepared bleached bamboo halfstuff from Carriage House Paper to use in the workshop. Below is a breakdown of the fibers we used and how they were processed. Paper fiber source 1: 100% bamboo canes (green and dried) Plant source: Bamboo Garden Fiber type: Grass Fiber weight: Approx. 1 - 1.5 dry pounds Fiber preparation: Crushed with hammer, mallets and feet. Approx. 1 ft. pieces submerged in water and left to rett for one week. Thoroughly rinsed prior to cooking in caustic (see next step) Caustic cooking solution: 10% soda ash (you could use lye and decrease cooking time to 1-2 hours) Cooking time: 6 hours Hollander beating time: 5 hours Sheet formation: Western style Drying style: With wet/dry vac. directly on mould and hung to air dry Paper color: Varies from yellow/gold to cream depending on thickness and cooking treatment Paper fiber source 2: 100% bleached bamboo halfstuff Plant source: Carriage House Paper (carriagehousepaper.com). They source the fibers from China. Fiber type: Grass Fiber weight: 1 dry pound Caustic cooking solution: n/a Cooking time: n/a Hollander beating time: 2 hours Sheet formation: Western style Drying style: With wet/dry vac. directly on mould and hung to air dry During the workshop students made papers with both of these fibers individually, a mix of the 2, as well as a blend of the bleached bamboo and blenderized bamboo leaves. They also used bamboo leaf inclusions. Here's a few photos from our process of making the bamboo pulp and from the class.

3 Comments

11/10/2017 09:39:08 am

Lawn tractors are great for larger gardens and they really can make a difference in the amount of time you spend cutting the grass. If you own a smallholding you will find that the lawn tractor can help you out in more ways than simply cutting the grass. Just remember to do your research before you rush out and purchase anything and you should be ok.

Reply

6/17/2020 12:41:16 am

This blog is providing valuable and unique information, I know that you take a time and effort to make a awesome article. Let make your life even better with game

Reply

Your comment will be posted after it is approved.

Leave a Reply. |

The StudioPulp & Deckle is a handmade papermaking studio located in Oregon. Archives

September 2023

Categories

All

|

RSS Feed

RSS Feed